Vino In My Dino

-

Last Lot In

September 30, 2016 16:49

Harvest 2016 is over for us with the last lot in of Merlot at noon today. Six weeks and two days ago we began with Sauvignon Blanc and today we took in this lot for the friends.red program. In fact it will be co-fermented with the Syrah from Ridge Ranch which was harvested yesterday. The fall weather is upon us on this cool 70 degree day with winds whipping up from the south, thin high clouds moving quickly over the blue sky and the wonderful aromas of fermenting wine wafting about the winery yard.

A toast with some Friends.Red in my Dino to another harvest, our 89th, in the tank. Thanks to the hard-working cellar and vineyard crews too!

-

Secret Agent: Block 007

September 28, 2016 16:55

Cabernet Sauvignon, the king of red wine grapes, gained its’ title because it is the most widely planted red wine grape in California with nearly 88,000 acres. (just for stats the next most widely planted grape is Zinfandel coming in at just over 47,000 acres). Secondly the out and out demand for the grape outstrips almost all others-Pinot Noir perhaps giving it a run for the money. We continue to farm 29 acres of this noble grape and as harvest winds down we take a look at a special block, 007, as it is harvested.

The final block off of our Cabernet Sauvignon vineyards was picked today and the light is at the end of the tunnel for everyone here at Pedroncelli. Named Block 007 by Jim Pedroncelli, who added a zero to the block name, it is a vineyard planted with specialized trellising and site specific qualities.

Block 007 was replanted in 1992—on the Scott Henry trellis system which splits the cordon arms into a double tier with the upper arm usually bearing about 3 tons of grapes per acres while the lower arm bears about 2 tons per acre. The vineyard land is well drained, right next to Canyon Creek where it is gravelly and ideal for growing Cabernet Sauvignon.

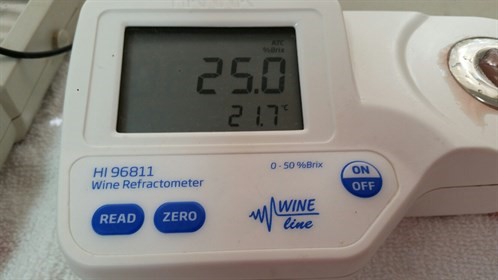

The warm weather we have had in September was welcomed as the key to ripening the grapes-coming in at an average of 26 degrees Brix. This level points to a rich and full flavored Cabernet. It is, after all, called hang time and the longer these grapes hang the better they develop. Balanced acidity, pH and sugar are the foundations of a great wine.

You may notice in the photo below there is a difference in how the grapes are being emptied into the crusher. We did run into a snag as harvest was winding down. The crushpad hoist for the gondola broke. With just days left to harvest the last of our vineyard blocks, vineyard manager Lance came up with a plan: borrow equipment. Favors were asked of three growers and they provided: the tractor, the bin lift and the bins. We managed to finish picking the Petite Sirah, Syrah and the Block 007 Cabernet this way. As is so typical of how we do business here in Dry Creek Valley, borrowing the important equipment to get the job done is an illumination of neighbors helping neighbors. It helps to have been here for so long but I suspect anyone needing help will find it among friends here in the valley. A toast to the vintage with a splash of Block 007 in my Dino!

Fully ripened Block 007 Cabernet Sauvignon headed for tank#105.

-

And Now For Something Completely Different: Night Harvesting the King

September 21, 2016 16:59

Cabernet Sauvignon is known as the ‘king’ of red wine grapes. We were the first to plant it in Dry Creek Valley over 50 years ago. Our 29 acres of vineyard thrive along the bench here in the valley, a mile or so west of the winery. Home to prune trees up until the 1970s when we purchased the property, the location’s rocky soil and cool nights help to develop the personality of our Three Vineyards Cabernet Sauvignon. Join me as we take a look at a first here at Pedroncelli: night harvesting Block DC02 destined for our Three Vineyard blend.

First let’s consider the vineyard and the way it was established as an important part of the story. When this block was replanted a few years ago, Vineyard Manager Lance Blakeley chose the straight vertical trellis style which would work for both hand and machine harvesting. He saw the need for some changes in the way we do things after years of doing it one way. Shortage of labor and skyrocketing costs all played into the decision. And last night, for the first time in our 89 years of farming our vineyards, we did something completely different. We machine harvested Block DC02. While my uncle John was dubious about the quality of grapes being machine harvested quite a bit has changed in the last 30 or so years. The vines are treated more gently as the machine moves down the row and the general MOG-Material Other than Grapes-is not as prolific as it is when picking by hand.

Winemaker Montse Reece said, “In the cellar this morning we saw very clean-picked grapes. Machine harvest has the obvious advantage of time, we picked this lot in only 3 hours compared to nearly 6 by hand. Picking at night allows the grapes to come into the cellar cooler than hand-picking during the day, preserving the aromas and flavors.” In fact I picked some Cabernet berries along the way and they were indeed cold-almost refrigerated after a warm couple of days. It proved a point. All these years I have been talking about how the fog influence is so important-keeping the grapes cool at night. And now we have night harvesting to thank for capturing the king of red grapes at its best. A toast to firsts with a splash of our Three Vineyards Cabernet in my Dino!

Vineyard manager Lance Blakeley oversees the first night harvest at Pedroncelli.

-

Capturing the King

September 14, 2016 17:05

Though Zinfandel is our flagship wine, Cabernet Sauvignon, AKA ‘the king of red wine grapes’,is equally as important to us. We farm 105 acres of grapes: 33 of them are Zinfandel and 29 are Cabernet Sauvignon. Between the two they make up 40% of our total production. As the harvest season continues we’ll look at our Cabernet Sauvignons: Wisdom, Three Vineyards and Block 007.

Wisdom Vineyard, West Dry Creek Road.

We were the first to plant this varietal in Dry Creek Valley. In 1965 John and Jim bought five acres a couple of miles west of the winery. For 50 years we farmed the piece which turned out to be a perfect spot for the King. When the vineyard chief, John Pedroncelli, agreed it was time to pull them up-who has ever heard of old vine Cabernet?-they did and replanted with site specific qualities in mind, A culmination of the years of 'wisdom' gained from knowig the land, the microclimate and the right grape. The decision was made to include a few rows of Malbec and 10 years later, at prime maturity, we are looking at a blockbuster vintage.

The vineyard was harvested on September 13. The Malbec, while it isn’t always ready to be picked at the same time, was ready to be included in this vintage and is being co-fermented in tank 092, one specifically designed for small lots. Montse Reece, winemaker, plans a four day cold soak so the must (juice and skins) has time to coalesce giving the wine a head start by adding more color and better aromatics pre-fermentation. The must will be inoculated with a Bordeaux strain of yeast and fermentation will take 10-12 days, with pumpovers being an integral part of developing complexity and flavor.

A toast to the Wisdom vineyard with a splash of Cabernet in my Dino!

-

Fermenting an Icon

September 8, 2016 17:09

Ten days ago the vineyard crew began picking Zinfandel from the home ranch. Home to our iconic Mother Clone Zinfandel, which has been growing here since the early 1900s, the vineyard contains first, second and third generation plantings. Head pruned, hillside location, hand harvested. Like we've been doing for 89 years.

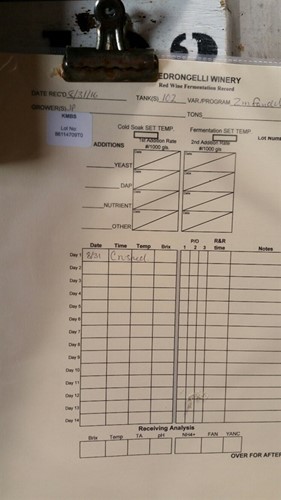

What happens after the destemmed berries and juice go into a tank? In this case I am following the first tank filled, #102.

Stainless steel Tank #102 holds 5500 gallons and this amount comes from 31 tons of Zinfandel. It is temperature controlled which helps to slow down the process. If it ferments too quickly then you don’t get much color or flavor so the idea is to give it some time. Once the tank is filled the concoction, now called must, settles for 24 hours.

Next, yeast is added to begin the conversion of sugar to alcohol. And it isn’t just any yeast used across the board. Winemaker Montse Reece makes sure to use the right one, Red Pasteur and is based on the varietal and the amount of the fermenting must. The tank is checked daily as fermentation takes the original Brix measurement of 26.2 to completely dry. This typically takes about 10 days.

And while it is slowly fermenting there is one other part of the process: the cap. The cap, which is comprised of the skins and seeds floating to the top, has juice pumped up from the bottom of the tank and is sprayed over the top three times a day. This is done to gain more flavor and color in the developing wine.

Mitch Blakeley, fourth generation Pedroncelli, works on emptying tank 102.

Finally, once fermentation has finished 10 days later, the tank is emptied, leaving the skins and seeds behind as it is pressed. The young wine is then transferred to a storage tank until the end of the year when the 2016 Mother Clone Zinfandel is put into barrels for a year. A toast to an icon, our flagship wine!

-

Harvesting an Icon

August 31, 2016 12:17

Our 89th harvest began two weeks ago. Today the vineyard crew picked several blocks on the home ranch. For us harvest doesn't really begin until our Mother Clone Zinfandel is brought in to the winery. Our flagship varietal, planted here in the early 1900s, is our iconic wine, the star of each vintage. Sourced from what is now second generation vineyard, the vines are nearly 40 years old and planted on the hillsides around the winery. A toast in my Dino with a splash of Zinfandel!

Here is a glimpse into the action. You get the idea going from vine to vine how intensive it is to pick grapes. Each bucket is run back to the gondola waiting at the end of the row.

First stop for the gondola is at the weigh station and for a sugar sample. Manuel Diaz, vineyard foreman, takes the sample to winemaker Montse for testing.

A cup of beautiful Zinfandel juice, ready for analysis.

The results are in! Manuel guessed 25 degrees Brix-the sugar level of the sample and he was right.

A short trip from the scale to the crushpad, 2016 Mother Clone is destemmed and sent to fermentation tank. This is when I wish we had smell-o-vision, the ripe fruit is so tantalizing.

The beginning of fermentation. We'll follow tank #102 as it begins its' wine journey.

-

First Crush: Harvest Memories

August 25, 2016 12:31

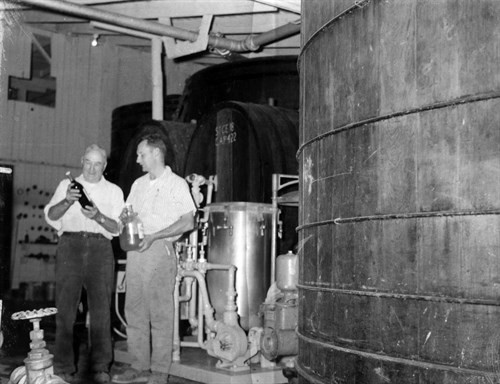

My uncle John was winemaker for nearly 60 years. His first crush, 1948, was captured in the oral history J. Pedroncelli Winery: An Ongoing Family Tradition about that first year on the job as winemaker. He had just completed his World War II service and attended Santa Rosa Junior College. He was ready for his first harvest.

“Well it was (a monster crush) for three people. We crushed maybe 800 plus tons of grapes with the three of us, and the good part about it was that we had only one red variety to do. We didn’t have to separate any varieties. Now we need to separate all these different varieties and it takes a lot more work. So we got the grapes crushed that year and probably sold it in bulk to someone. We were selling a lot of bulk to Italian Swiss Colony, Petri and Gallo was on the scene. We weren’t making a lot of money doing that, probably got about forty-two cents a gallon for it. I don’t remember what the price of grapes was at the time.”

Brother Jim filled in the pricing: “I think grapes peaked out at $120 a ton during the war, then they dropped down to $40 or $50 a ton. I remember that one batch of wine I think we sold for about thirty-two cents a gallon.”

John continued, “The cooperage was all redwood tanks. In future years, 1955 or 1956, we got our stainless steel tanks. But in the forties everything was redwood including the fermentation tanks.

Winemaking used the standard old-style method, adding yeast. I had a helper from Fessler Laboratories who tested all our wines for us. He took the sugar and alcohol, which are things I didn’t do at the time. I had the poor guy do every fermenter, which was up and beyond the call of necessity.”

A toast to John with some Zinfandel-which comprised the ‘red variety’ he refers to in the oral history.

Here John is standing in the cellar with his father Giovanni. The redwood tank to his left was one of many that lined the cellar. This photo is circa early 1950s.

-

Harvest 2016 Begins

August 17, 2016 12:39

We began our 89th harvest with Sauvignon Blanc from our East Side Vineyards located a mile west of the winery. We started harvest on the same date one year ago!

Here are some snapshots from the big event:

Winemaker Montse testing for Brix at the harvest lab. Measured 23.5-nice and ripe.

Next stop is the crush pad for destemming.

From the destemmer into the press-the rice hulls you see are part of the process to make sure we get all the juice from the skins (and the hulls are inert and add no flavor to the wine).

The 2016 vintage of our Sauvignon Blanc has been pressed, the juice flowing into the sump and on its' way to the fermentation tank. Let the vintage begin!

-

Harvest Memories: The Winemaking Team

August 16, 2016 12:47

Cellar Master Hipolito Cano

His first harvest was 1990 having spent the previous two years out in the vineyard. He says it was a ‘pressure cooker’ situation because he had to learn as he went along. Going from tanks to presses to crushpad he did his best to keep up with everyone too busy to stop and explain. He became a quick study.

John Pedroncelli always advocated the team effort. He noted the cellar crew is great and it is a plus having a team that has a few years of experience behind them. It is like a well-oiled machine and they are motivated to get the task done and lend a hand when needed. He compared harvest time to being a singer and having stage fright right before going on stage-the happy day is coming and once it is here you begin to sing and everything is in tune. You find the melody and keep singing.

It doesn’t matter how prepared you are, harvest always takes us by surprise. Each year is a new challenge but I’m eager to take on the challenge.

Vineyard Manager Lance Blakeley

From early to late harvests it’s the best part of the year. There is more of a laser focus because you are doing one thing at harvest-picking grapes when at other times of the year you are multitasking. Harvest focuses the efforts on one thing: grapes which are the foundation of wine.

He noted there are lots of characters when it comes to our history of grape growers and cellar workers who have been part of our harvests. One grower brought their grapes in an old truck bed on top of their pick up-a challenge when it came time to empty the grapes into the crusher. We were often the first place growers sold their grapes to and some have stayed and others moved along to other wineries or even started their own winery.

He remembers the first time we received machine harvested grapes and reminisced that John Pedroncelli didn’t like the quality in the fruit. He noted machine harvesting has come a long way in preserving quality but back then it was pretty rough and created lots of juice and fermentation happening before the must went into the tank. He also feels that white wine varietals can handle being machine harvested while red wine varietals seem to keep better quality when hand-picked. Every vintage brings different challenges (weather, low or high production, rain, heat) and is expressed in our wines and is due in large part to hand picking our vineyards.

Winemaker Montse Reece

It was 1993 and her first harvest experience was while studying winemaking at university. It took place at a small wine cooperative in the Penedés. She had one other cellar guy working with her and the winemaker was 100 kilometers away-but she had his phone number! She learned a lot by her experience there bringing in white and red wine grapes and making all the decisions about fermentation. She called the winemaker many times for guidance and ultimately the wines were guided by her hand.

She is married to Ferrari-Carano Winery's maintenance manager Pat Reece so harvest is a time to balance their lives-they have a seven year old daughter Marion who needs time with Mom and Dad. Sometimes she comes to work on Saturdays and experiences a work day with mom.

The first year she worked with John Pedroncelli they were talking about when to bring in the grapes from a particular vineyard. It looked like Sunday would be the best time to harvest them but John advised Montse: “People are first.” He felt giving them a day off, after working so hard, would be best. “The grapes will be fine-we’ll harvest on Monday.” She says he was revolutionary because he didn’t push people over their limits and this concept is very unusual during the busy harvest time.

A toast to our winemaking crew-with some Sauvignon Blanc in my Dino-since this is the first varietal we pick each harvest.

Here is a throwback photo since John was an integral part of putting the team together. Here he is amidst his 'crew': Hipolito, John, Montse and Lance.

-

Harvest Memories Part 2

August 10, 2016 12:55

My family and I grew up in the middle of things, literally, since our home was ‘wine central’ to the vineyards and winery. While there were many activities throughout the year I think harvest was the most exciting. It is the culmination of hard work getting the vineyard ready and sitting on pins and needles while watching the weather throughout and always hoping the rain stayed away until after the last grape was picked.

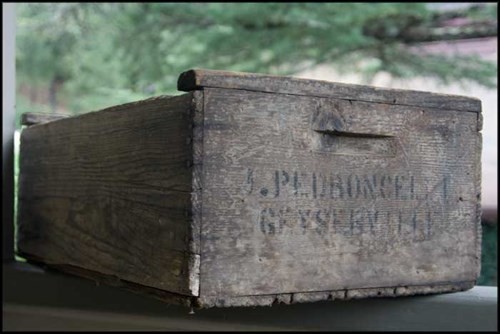

My mom Phyllis remembers weighing in the trucks during the first harvest after they had moved into the family home. At that time grapes were picked into wooden boxes that came stacked high on truck beds. When my sister Joanna was born in 1966 mom recalls taking her in her infant seat to weigh the grapes, watching from her perch nearby. Many of the Italian growers brought more than grapes and the chestnuts, mushrooms and other fall crops were left for the family to enjoy. The names rolled off her tongue like it was yesterday: Capucci, Zini, Buchignani, Teldeschi, Pedroni and Glaser (the German in the bunch).

My sister Lisa remembers the sweetness in the air of juice just before fermentation followed by the pervasive smell of fermenting grapes which is quite pungent. Also the constant noise of the equipment running nearly around the clock. The gruff Italian growers would visit the tasting room once their grapes were weighed in and on the crushpad. Lisa would pour them a standard tasting sample and they’d tell her it was a drink they were after not a taste, so fill it up! We both recalled when we’d take grapes up to the house and ‘make wine’ by squeezing them into our plastic wine glasses from our plastic dinner ware set. Pretty certain we left a sticky mess on the table. Sorry mom!

Cousin Richard, who also grew up on the family property, recounts the bees, the heat, sweat, stickiness, blood, thirst and all-around hard work of being a go-fer in the vineyard and cellar. He remembered when some growers would throw the sweetest grapes on top and objected when he took the sample from the whole load. They wanted their sugar sample to be high-back then they were paid on how ripe the grapes were. I think he says it best here “The smell of must will stay with me for the rest of my life.”

I'll toast to another round of memories with a splash of Cabernet in my Dino.

Here is the typical grape box Phyllis Pedroncelli remembers, this one from our own stash. Imagine 30 or 40 of these being emptied one at a time into the crusher-back breaking work!

Categories

- COVID

- Follow the Vineyard

- Note from Home

- PairItWithPed

- Pandemic

- pedroncelli

- Port

- Postcards from Home

- Pruning

- Seasons in The Cellar

- Tasting Room

- Thanksgiving

- Vintage Notes

- Winemaking

- Women's History Month

Recent posts

-

91 Years Later

-

Come Over October: It's About Community

-

Come Over October

-

A Legacy Continues!

-

Everything Old is New Again

Popular tags

- Library Wine

- Sauvignon Blanc

- Seasons in The Cellar

- Sonoma County

- cooking with wine

- Finding Your Roots

- Cookies

- Four Grapes Port

- newsletter

- PairitwithPed

- Lake Sonoma

- Homecooking

- Anniversary

- Habit

- Merlot

- OpenThatBottleNight

- Cabernet Sauvignon

- COVID Coffee Chat

- Bushnell Vineyard

- French Oak

- note from home

- Crop set

- COVID19

- Block 007 Cabernet Sauvignon

- Oak

- Pandemic

- Barrels

- Pruning

- Pantry

- food and wine

- Estate Vineyard

- family

- Cellar Master

- Recipes

- Rosé

- Heat wave

- Pedroncelli

- Mother Clone

- Reserve

- 1974 Cabernet Sauvignon

- American Oak

- Follow the Vineyard

- Harvest 2022

- Holding steady

- Schotzki

- Easter

- Courage Zinfandel

- Down to Earth

- cheese

- Dry Creek Valley